![]()

![]()

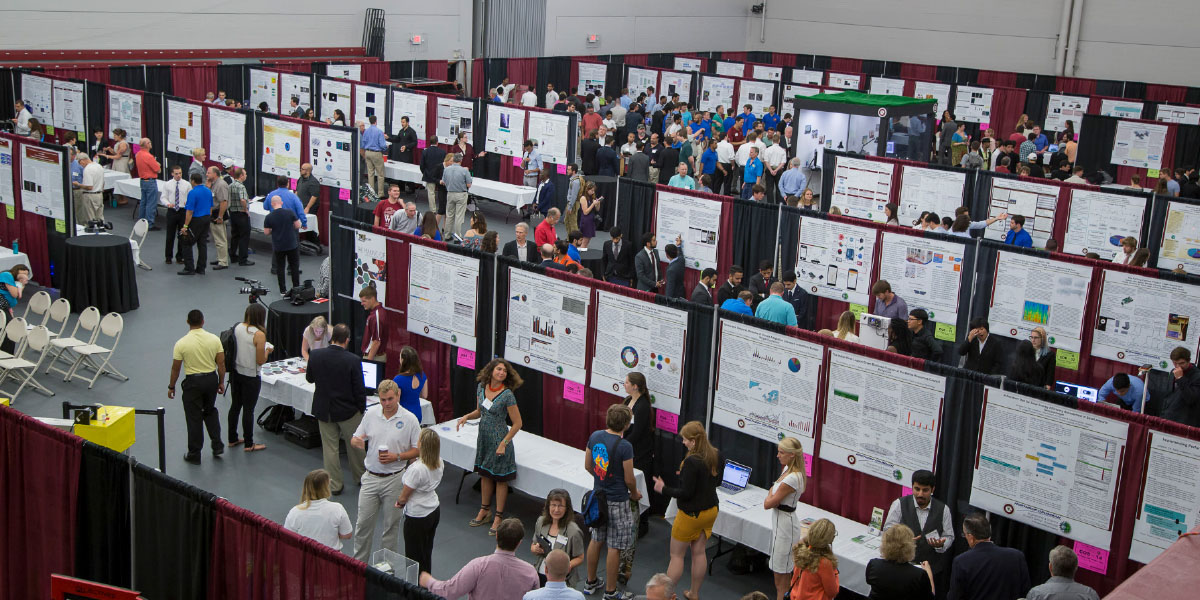

Walking through Florida Institute of Technology’s cavernous Clemente Center in Melbourne on a warm spring day, the excitement is electric. Students dressed to impress stand in long rows, displaying hardware, software, and all manner of scientific and engineering-related equipment and materials. They eagerly chat with one another, visitors, and, perhaps most importantly, industry experts who walk from table to table, asking questions and offering insightful input as they judge the efforts.

What is it they are evaluating? Kidney disease research. A satellite simulator. Even a 3D-printed, pediatric, prosthetic arm.

Seniors in Florida Tech’s colleges of engineering and science annually exhibit their academic achievement and technical prowess at the Northrop Grumman Engineering and Science Student Design Showcase, the capstone experience for undergraduates. This year, the showcase featured 139 projects on a wide range of topics.

Hands-On High-Tech

This nearly 60-year-old private technological university was founded at the dawn of the space race as a “night school for missile men” working at NASA’s nearby Cape Canaveral. As times have changed, the university’s focus has widened substantially. The scope of the work being done by today’s students reflects that changing strategy.

These enthusiastic young people are doing hands-on work on dynamic projects as undergrads that many graduate students at other universities would rarely get to do. That’s an outstanding—and unusual—attribute of the university. It means that its students are that much better prepared for the workforce upon graduation. From a business officer’s perspective, that’s significant. Giving young people the tools that they need to achieve success in the workplace speaks well to the university’s future prospects for growth and prosperity.

Corporate partnership is key to Florida Tech’s showcase success. In 2009, a $1 million endowment from nearby Northrop Grumman Corp. provided ongoing support for the students’ work. Company officials annually present two special “Best in Show” prizes at the showcase for individual projects from the College of Engineering and the College of Science, to recognize and encourage the student effort. Other leading companies in the community, including Harris Corp., participate as judges and advisers.

“Given the way that Florida Tech was founded by engineers and created as a university to work closely with industry, it’s natural that our students earn these practical experiences,” says T. Dwayne McCay, who took office as president of Florida Tech on July 1. A former NASA engineer, McCay previously served as the university’s executive vice president and chief operating officer. For him—and Florida Tech—continuing to build lasting relationships with the private sector is a priority.

Students at the Center

“Florida Tech’s focus is student success,” McCay says. “We believe that in order to create that ultimate career success, students must have access to high-tech opportunities and collaborate with respected researchers as early in their academic careers as possible.”

Independent assessment confirms that Florida Tech’s approach is working. Last summer, Florida Tech was recognized as one of the nation’s 50 most entrepreneurial research universities, according to Forbes magazine. The Forbes list spotlighted the 50 research universities that the magazine determined were “the most entrepreneurial” in the nation. It calculated this based on the numbers of alumni and students who have identified themselves on LinkedIn as founders and business owners, with an adjustment made for student body size. This was the second consecutive year that Florida Tech was included on the list. It is one of just two Florida universities in the 2015 rankings, and at No. 33 is ranked ahead of several much larger institutions.

Budding entrepreneurs. By giving students entrepreneurial-style tools and experiences throughout their college career, the university is doing a better job of preparing them for the world of work. The synergy between education and experience remains a hallmark of the Florida Tech learning environment and speaks to the value proposition of higher education. So how does the showcase experience make a real difference in a student’s education and future prospects?

Participating students must conceive, research, and/or design and implement their projects, gaining hands-on experience in applying science or engineering knowledge and the fundamental principles of their respective majors. It allows them to experience the difference between computer-modeling something and making it in the real world, said Laurie Guiser, Florida Tech’s student project director for the College of Engineering.

“Understanding design and actually designing and executing it are different,” she says.

Michael Grace, a showcase coordinator and senior associate dean of the College of Science, added, “Conducting projects that are presented at the showcase allows students to apply creative thinking and practical application, while they learn valuable lessons in teamwork, professionalism, and leadership. Florida Tech students are generating novel data, creating new products, and solving important, real-world problems.”

A number of departments participated in this year’s events, presenting a wide variety of novel ideas.

- College of Engineering. From Aerospace Engineering came Sharkbait, an “unmanned underwater-air hybrid vehicle” that can travel from the water to the air and back again. The machine is a cylindrical vehicle with wings that can extend to 90 degrees for takeoff and flight and then retract flush with the body for underwater usage.

Another College of Engineering project was Solarizer, designed by the Biomedical Engineering team. This portable, solar-powered autoclave could bring properly sterilized medical equipment to areas with limited resources.

- College of Science. Research projects this year included the “Rocket Cable Model for Lightning Protection,” which describes a newly developed predictive model for lightning’s effects on spacecraft as they await launch.

- Mathematical Sciences. “Clinical Genomic Risk Factors of Chronic Kidney Disease” analyzes a very large clinical data set to accurately predict the progression of chronic kidney disease and stratify patients into risk categories. The student researchers predict that this work will ultimately lead to new therapeutic targets for drug development.

- Biological Sciences. The project “Thermally-Induced Shift in Biomechanical Performance of the Invasive Lionfish, Pterois volitans” described how the feeding mechanism of the predatory lionfish changes with temperature. This work may help explain how lionfish have so rapidly spread throughout the Western Atlantic and may contribute to efforts aimed at controlling its economic and ecological impacts.

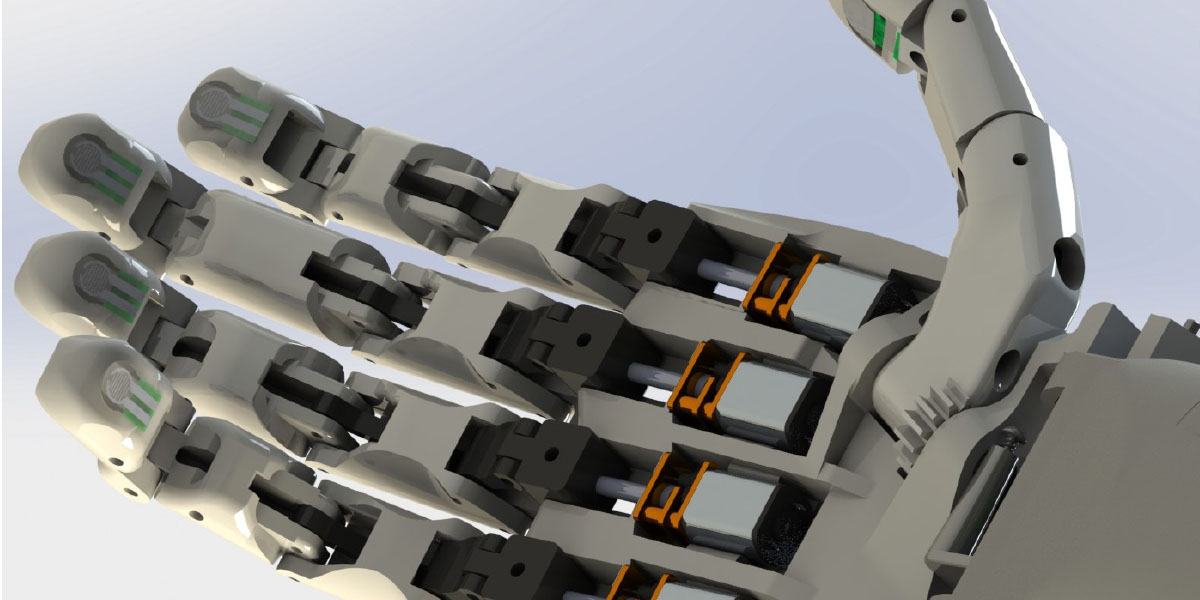

- Department collaboration. Perhaps the most intriguing project presented this year gives new hope to young people. A team of computer, mechanical, and biomedical engineering students presented a low-cost, 3D-printed, prosthetic arm, ultimately winning the President’s Cup for their efforts. “It’s a brilliant, forward-thinking idea,” said former Florida Tech President and CEO Anthony J. Catanese, who retired June 30. “That’s exactly the kind of ingenuity we strive to inspire with our Student Design Showcase.”

Their project, called PriMA Prosthetics, provides touch-sensing capabilities for patients, along with heating and cooling of the residual limb to prevent sweating and sores during high- or low-temperature environments. The arm is operated on myoelectric EMG (electromyography) signals from the bicep, and the hand can firmly hold about 50 pounds. The students say it is also the first one in market history to provide touch-sensing capabilities that allow the user to determine the strength necessary to pick up or hold an object. It also can be produced at an affordable pricing point of $1,500, which can save patients thousands of dollars over their lifetime use. Each arm comes equipped with an android app, which allows the user to easily toggle through and select gestures suitable for their work environment, and file maintenance requests when necessary.

Mechanical engineering senior Doug Brown says his team’s project is essential to improving lives of people who are struggling with limb amputations or birth defects. The arm has the ability to drastically undercut the market by providing one of the most affordable prosthetics available, coupled with some of the highest functionality one can find. The team was inspired to pursue such an advanced prosthetic because of the deprivation of life seen in the patients they analyzed. The average prosthetic arm with basic functionality starts at $50,000.

“Most insurance companies won’t cover the annual purchase or renovations of prosthetics at this price tag, forcing the financing onto the patient,” Brown says. “For instance, if you’re a middle- or lower-income family with a child affected with limb deficiencies, it would cost on average between $750,000 to $1 million to raise said child to an adult age of 18.” According to Brown, the project was the definition of real-world experience. It was a testament to see how much the team accomplished in a short six-month time frame.

Inspiring Commitment

“We were all handed a project we knew literally nothing about and managed to put in enough work to make a difference,” Brown says. “Not to mention it forced us to have in-depth, hands-on experiences with a variety of disciplines and mechanical systems.” Brown advises students to push themselves to the breaking point when it comes to whatever project they may be working on.

“For us as a team, we were able to achieve so much because we simply engulfed ourselves in information,” Brown says. “To be honest, some of our most significant discoveries and breakthroughs happened at 3:30 in the morning after seven hours of constant work.”

That outstanding commitment was apparent across the board with this year’s showcase projects. With this next generation of scientists and engineers poised to enter the workforce, the world is indeed in good hands. (For video and

more photos from Florida Tech’s Northrop Grumman Engineering and Science Student Design Showcase, visit www.fit.edu/student-design/.)

CATHY WOOD is senior vice president for financial affairs and chief financial officer, Florida Institute of Technology, Melbourne.

RESEARCH INSTITUTIONS: